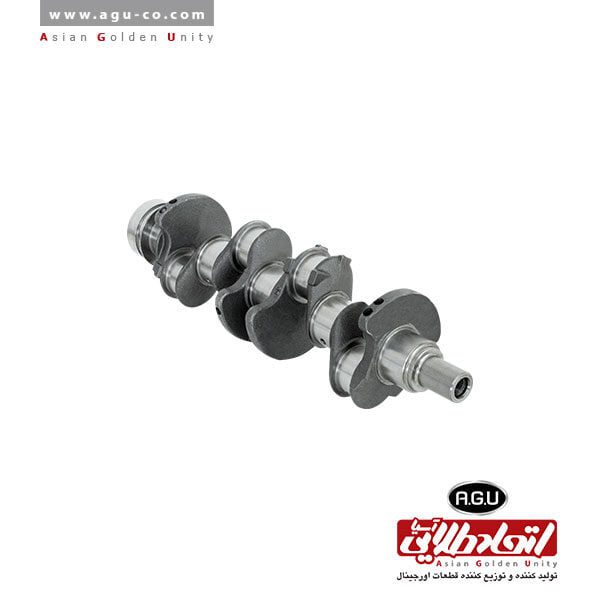

The Connecting Rod is one of the vital components of the engine, responsible for connecting the crankshaft and the piston. The larger end connects to the crankshaft, and the smaller end connects to the piston. This part must be made of steel to withstand the impacts transferred from the piston to the crankshaft, ensuring sufficient strength and durability.

The Three Main Parts of a Connecting Rod:

-

-

Larger End (Bearing)

-

-

-

Body

-

-

-

Smaller End (Bearing)

-

The smaller end is connected to the piston by a component called the gudgeon pin, which absorbs the initial impact from the piston. This impact is transferred through the body to the larger end and finally to the crankshaft. The smaller bearing is usually made as a single piece, while the larger bearing is typically designed in two pieces, connecting to the crankshaft with bolts and nuts. In some cars, both ends are designed as single pieces, which requires the crankshaft to be modular for assembly or disassembly.

Connecting Rods by Ettehad Talayi Asia Company are produced with the highest quality and efficiency, using the best alloys to ensure strength and durability against piston impacts.

Signs of a Failing Connecting Rod:

A failing connecting rod can cause severe damage, so it’s important for car owners to be aware of the symptoms.

-

-

Unusual Engine Noise: One sign of a failing connecting rod is abnormal engine noise, which increases as the engine speed increases, indicating a higher likelihood of damage.

-

-

-

Knocking Noise: To prevent wear and damage, all moving parts in a car must be lubricated. Connecting rods are moving parts, and without proper lubrication, a knocking noise may be heard from the engine.

-

-

-

Oil Leaks: Another sign of a failing connecting rod is oil leakage from the engine.

-

-

-

Metal Parts Ejecting: In very rare cases, a failing connecting rod can cause metal parts to be ejected from the engine.

-

Causes of Connecting Rod Failure:

-

-

Improper Assembly: If the connections to the piston and crankshaft are not correctly assembled, the connecting rod is likely to fail.

-

-

-

Severe Piston Impact: If the impacts from the piston exceed normal limits, the connecting rod may break. Premature or abnormal combustion in the cylinder is a common cause of such severe impacts.

-

-

-

Lubrication Issues: As mentioned earlier, proper lubrication of moving parts is crucial. If lubrication is insufficient or incorrect, the likelihood of connecting rod failure increases significantly.

-

-

-

Downshifting at High Speed: Incorrect downshifting at high speeds can damage the connecting rod.

-

-

-

Severe Collisions: Severe accidents, especially frontal collisions, can cause the connecting rod to break or fail.

-

-

-

Poor Quality: Low-quality materials and inferior alloys can lead to the connecting rod breaking or failing.

-